18072885002

Single-village water supply stations are important facilities for providing safe drinking water in rural areas. They are characterized by small scale, scattered distribution, diverse water sources and complex water quality. Traditional water treatment processes (such as sand filtration, slow filtration, etc.) have certain limitations in dealing with complex water quality and ensuring water supply safety. Silicon carbide membranes provide an innovative and reliable solution for single-village water supply stations with their advantages of high efficiency filtration, pollution resistance and easy maintenance.

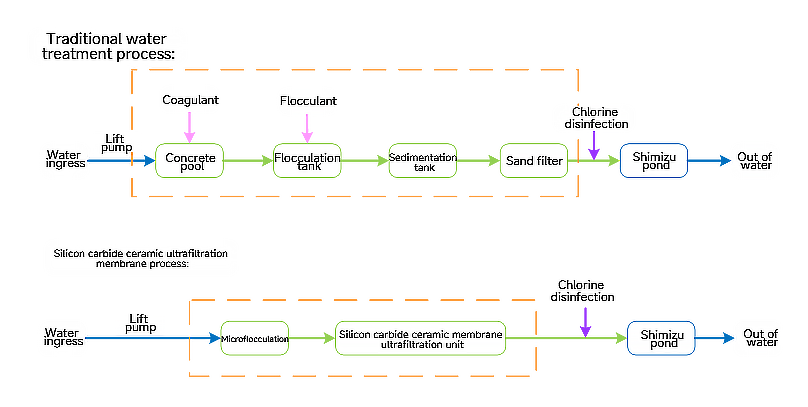

1. Comparison with traditional water treatment processes

The traditional water treatment process of single-village water supply stations generally removes organic matter and viruses through processes such as flocculation, sedimentation, filtration and disinfection. The overall process is long and slow. It usually requires multiple large structures such as sedimentation tanks and filtration tanks, and maintenance is more difficult.

The silicon carbide ceramic membrane process is simple and direct. The silicon carbide ceramic membrane process uses standardized equipment with high equipment integration. When treating the same scale of water, the equipment occupies a smaller area. The entire process does not require complex chemical agent additions and multi-stage treatment processes. Efficient filtration can be achieved only through the physical interception of the membrane. The equipment adopts automatic operation, and can realize one-button start and stop, online monitoring and other functions through the control system, which greatly reduces the difficulty of operation and labor maintenance costs.

2. Advantages of silicon carbide ceramic membrane in single village water supply station

1.Good effluent quality

The water quality can meet the standard of direct drinking water, and some indicators are better than European and American water quality standards. The turbidity of produced water is <0.1NTU, 100% of bacteria are removed, and the removal rate of Giardia and Cryptosporidium reaches 6 logs, which effectively ensures the safety of drinking water microorganisms.

2.Stable effluent quality and strong impact load resistance

When natural disasters such as heavy rains and floods cause the raw water quality to fluctuate greatly, the ultrafiltration membrane can ensure the stability of the effluent water quality.

3.Short process and small footprint

The process is simple and compact, with a small footprint, standardized equipment, and a short on-site construction period.

4.High flux

The flux is as high as 200-400LMH, with large output and high efficiency per set.

5.Anti-pollution

Silicon carbide ceramic membrane has strong anti-scaling and anti-microbial capabilities, does not require frequent cleaning with chemicals, and can operate stably in areas with limited agricultural drinking water sources.

6.Long life

Silicon carbide ceramic membrane is formed by recrystallization and sintering of silicon carbide material, and its service life is long, up to 15-20 years or more. No need to change the membrane frequently.

7.Simple operation and maintenance

Silicon carbide ceramic membrane technology equipment operates automatically, operation and maintenance are simple, and the operator level requirements are low.

3. Application case of silicon carbide ceramic membrane in single village water supply station

990m3/d silicon carbide column membrane rural drinking water expansion project

30m3/d silicon carbide positive pressure flat membrane agricultural drinking water system project

50m3/d silicon carbide negative pressure flat membrane agricultural drinking water system project