18072885002

JMFILTEC silicon carbide ceramic membrane technology in

PCB electroplating wastewater treatment

Printed Circuit Boards (PCBs) are crucial components in the production of electronic products. Their manufacturing process generates PCB wastewater, which, if left untreated, can harm the environment and even human health. In actual production, PCB wastewater can be mainly categorized into organic wastewater and electroplating wastewater. Organic wastewater primarily consists of stripping and developing wastewater, characterized by a high pH, complex composition, and significant fluctuations in quality and quantity. Electroplating wastewater is characterized by a low pH, high levels of certain metals, and the presence of complexed heavy metals.

In this article, we will explore in depth the characteristics and treatment technology of MCR membranes applied to electroplating wastewater in PCB circuit board wastewater.

I. Challenges in Treating PCB Electroplating Wastewater

● Highly corrosive: The wastewater has a stable pH of 2-4 and contains acidic components such as sulfuric acid and hydrochloric acid. This places extremely high demands on the corrosion resistance of the treatment equipment materials. Traditional organic membranes or metal equipment are easily corroded, resulting in short service life and frequent maintenance.

● Heavy metals are complex in form: in addition to free copper and nickel ions, they also contain a large number of complexed heavy metals. Conventional coagulation and precipitation are difficult to break the complexes, and the heavy metal removal rate cannot meet the standards.

● Resource recycling is difficult: Traditional processes often solidify heavy metals in the form of sludge, which not only wastes the value of precious metals such as copper and nickel, but also generates a large amount of hazardous waste and has high disposal costs.

II. Process Flow of MCR Membrane in PCB Electroplating Wastewater Treatment

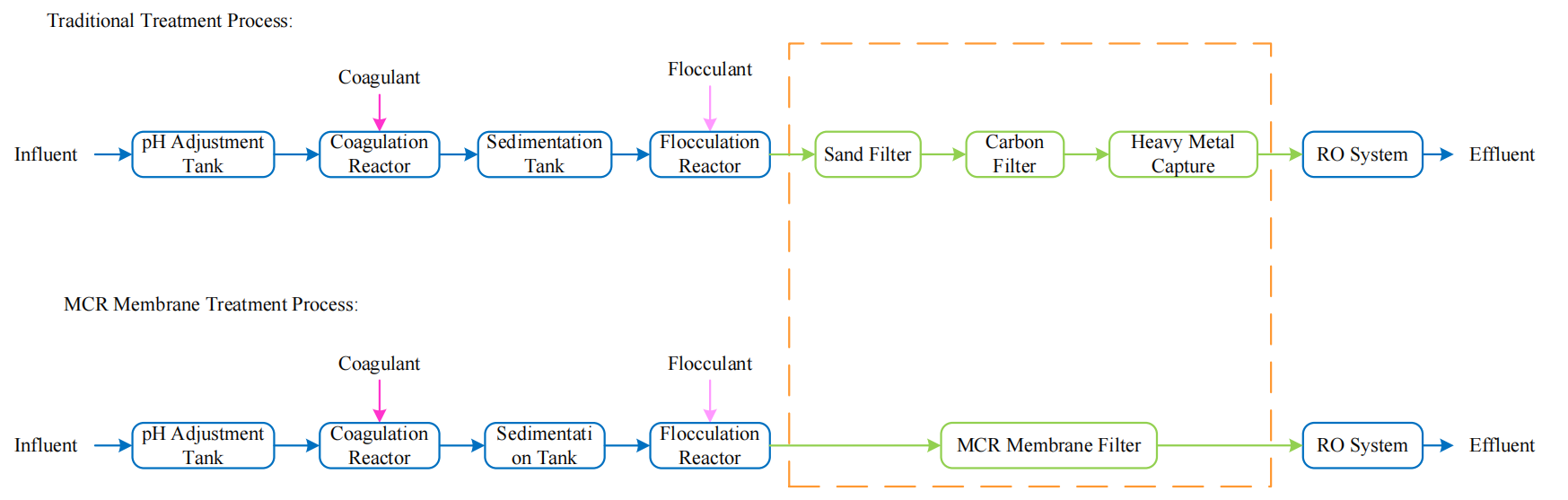

In the treatment of PCB electroplating wastewater, traditional processes require multiple independent steps such as sand filtration, carbon filtration, and heavy metal capture devices. The process is cumbersome and requires a large area. The recovery of heavy metals is also inefficient due to incomplete interception and limited concentration .

As the core of the MCR membrane process, JMFILTEC silicon carbide ceramic membrane can directly replace these steps, integrating multiple processing functions in one step, greatly simplifying the processing steps and reducing the footprint; the MCR membrane efficiently intercepts and concentrates heavy metal flocs, making the heavy metal recovery effect better, and achieving the treatment goal of "simple steps, low footprint, and good recovery".

The simplified process flow diagram is as follows (for reference only):

III. Advantages and Value of Silicon Carbide Ceramic Membranes

As the core of MCR membrane technology, JMFILTEC silicon carbide ceramic membranes offer the following technological advantages and application value in PCB electroplating wastewater treatment:

● Strong corrosion resistance: It is made of silicon carbide material that has been recrystallized and sintered at high temperature. It has strong corrosion resistance and acid and alkali resistance, and can adapt to the complex water quality environment of electroplating wastewater for a long time. There is no need to worry about operational failures caused by material corrosion.

● High-efficiency separation: Relying on the nanoscale pore size and molecular retention reaction characteristics of silicon carbide ceramic membrane, it can efficiently retain impurities and heavy metal flocs in water, and the produced water quality fully meets the influent requirements of the subsequent RO system . It has a high water recovery rate and low sludge production.

● High cost-effectiveness throughout the entire life cycle: with a lifespan of up to 20 years , it can operate stably for a long time, reducing equipment replacement investment; the process flow is simple and compact, easy to integrate, and occupies a small area; it has strong anti-pollution performance, is not easy to clog, and has a long cleaning cycle.

● resource recycling effect : Valuable substances such as metals can be recovered from the intercepted water during the treatment process, realizing resource reuse.

IV. Summary

In summary, as the core of the MCR membrane process, JMFILTEC silicon carbide ceramic membrane can effectively solve the problem of PCB electroplating wastewater treatment, providing a reliable solution for PCB companies to achieve environmental compliance, cost reduction and efficiency improvement, and resource recycling.