18072885002

Silicon Carbide Flat Sheet Membrane System

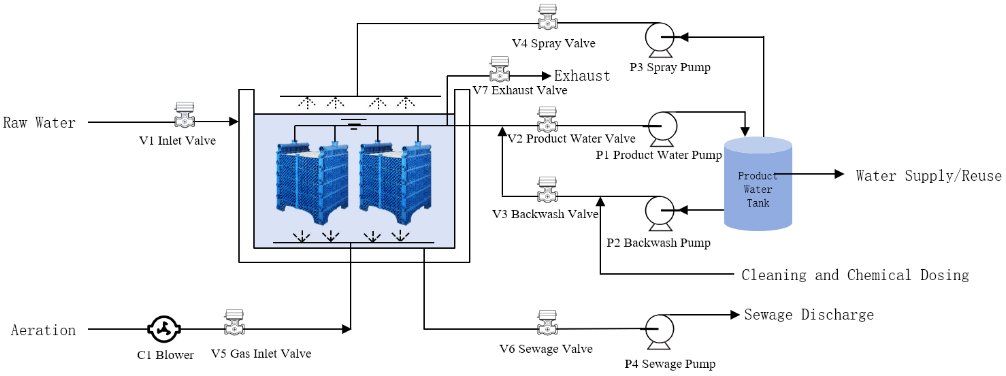

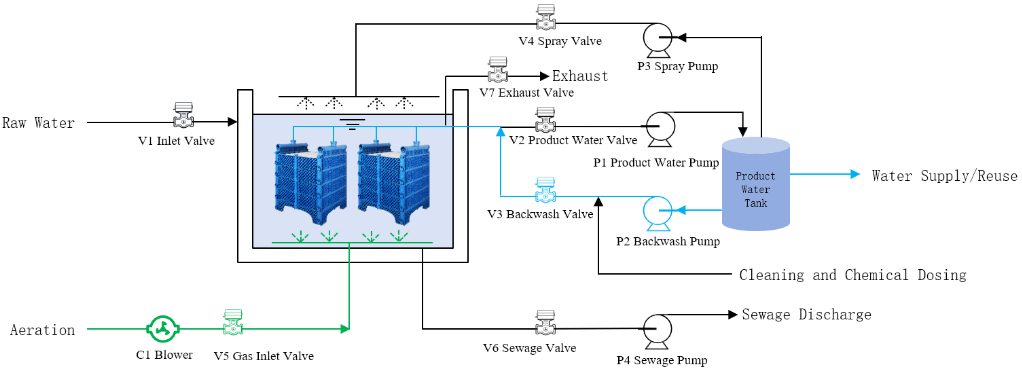

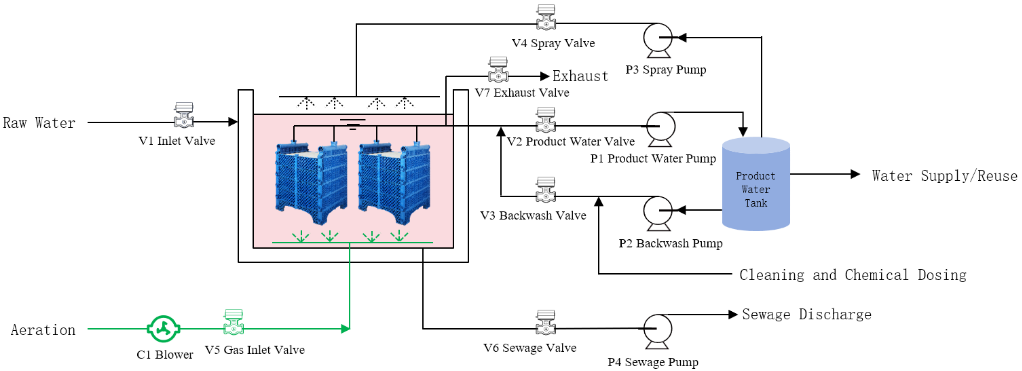

Silicon carbide flat sheet membrane technology belongs to the category of submerged ultrafiltration. Its core application involves directly immersing the silicon carbide flat sheet membrane module in the raw water or wastewater tank to be treated. Driven by external power (usually negative pressure provided by a permeate pump or siphon), water and particles smaller than the membrane pores permeate through the membrane layer, while particles larger than the pores are retained, thus achieving solid-liquid separation.

Ultrafiltration cleaning processes are divided into physical cleaning and chemical cleaning. Physical cleaning includes backwashing, spraying, and aeration processes. Backwashing uses reverse water flow (entering from the permeate end of the membrane module and permeating through the membrane pores) to remove deep-seated and surface contaminants from the membrane pores. Spraying and aeration processes use hydraulic impact or gas disturbance to assist in the removal of impurities adhering to the membrane surface. Chemical cleaning uses chemical agents to remove colloids, organic matter, inorganic salts, and other contaminants formed on and inside the ultrafiltration membrane, including chemical maintenance cleaning (CEB) and chemical restorative cleaning (CIP).

01 Silicon Carbide Ceramic Flat Sheet Membrane System Operation Modes

The operation modes of the silicon carbide flat sheet membrane ultrafiltration system are as follows:

The membrane filtration process includes the following steps:

◆ Product Water: The product water step removes contaminants such as metal oxides, suspended solids, and bacteria;

◆ Backwashing: Periodic backwashing is required to remove the filter cake layer from the membrane surface;

◆ Spraying: Water is sprayed directly onto the top of the filter tower, improving backwashing and cleaning efficiency;

◆ Aeration: Air comes from the bottom of the filter tower, improving the backwashing and cleaning process;

◆ Chemical Circulation: Removes fouling or scaling from the inside of the membrane sheets;

◆ Chemical Cleaning: Removes fouling or scaling from the outside of the membrane.

02 Silicon Carbide Ceramic Flat Sheet Membrane System Operation Process

1. Water Injection & Air Venting

Open the top air vent valve and the inlet valve to introduce raw water into the membrane tank, venting the air from the system.

Startup Timing: The system is first run or after the silicon carbide ceramic flat sheet membrane system has been emptied of liquid.

2. Filtration

Filtration uses a pump to create negative pressure (vacuum) inside the membrane. This pressure difference drives water molecules through the membrane, allowing purified water to flow out from the permeate side, while contaminants are retained.

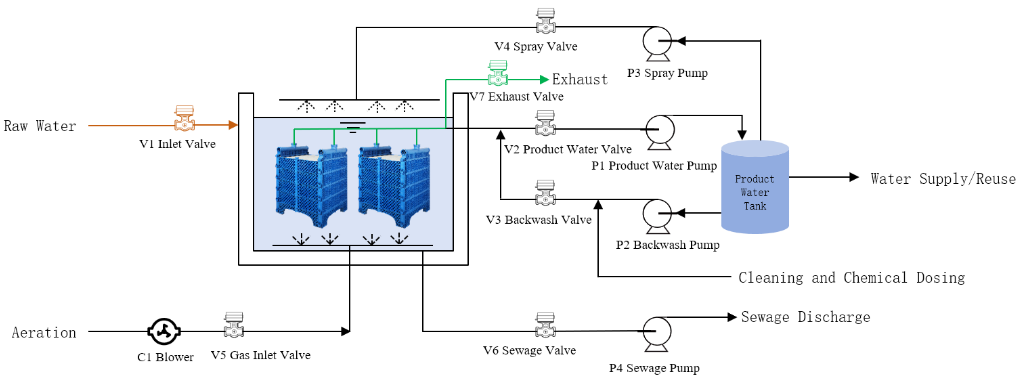

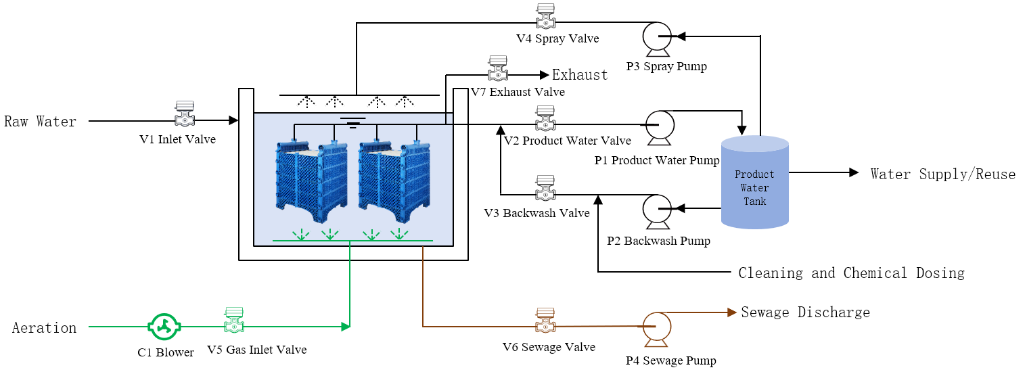

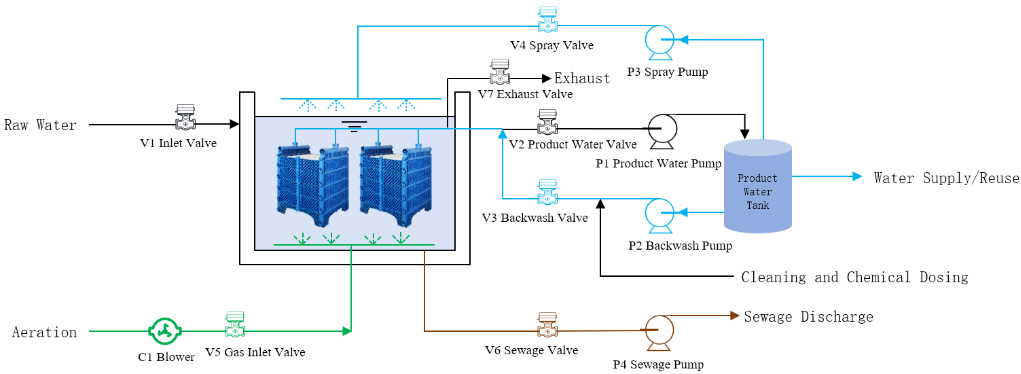

3. Physical Cleaning

Physical cleaning consists of two stages. The first stage uses backwash pumps and aeration devices for backwashing and aeration to address the impact of the filter cake layer on the membrane system's performance. The second stage, performed before chemical cleaning, involves emptying the membrane tank and using a spray cleaning process combined with backwashing and aeration to thoroughly physical clean the membrane elements, creating favorable conditions for chemical cleaning.

① Backwash & Aeration

② Membrane Tank Emptying & Aeration

③ Spraying & Backwashing & Aeration & Emptying

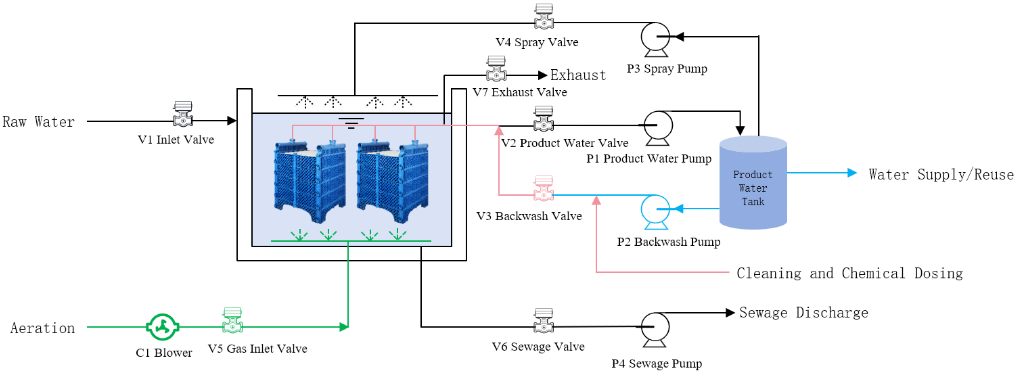

4. Chemical Cleaning

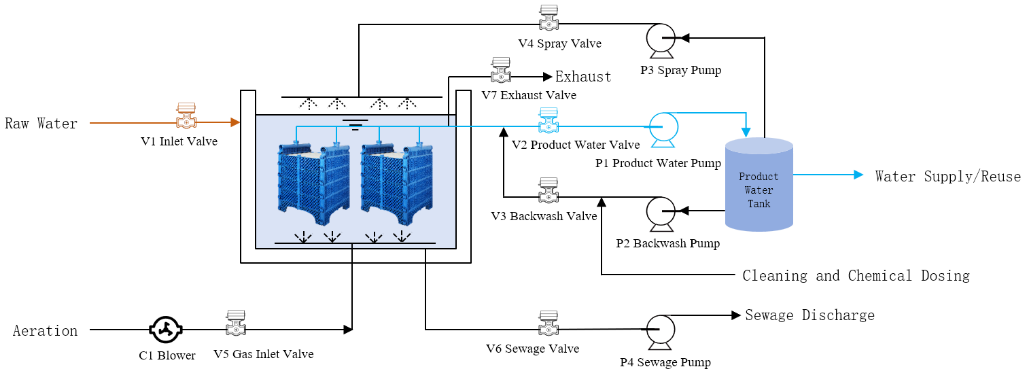

Chemical cleaning is divided into Chemical Maintenance Cleaning (CEB) and Chemical In-Place Cleaning (CIP).

① Chemical Maintenance Cleaning (CEB)

Chemical Maintenance Cleaning (CEB) involves adding chemicals to the backwash water to improve the cleaning effect.

② Chemical In-Place Cleaning (CIP)

When the above cleaning methods fail to restore flux or the permeate pressure reaches the CIP cleaning value (-40 kPa), chemical in-place cleaning (CIP) must be initiated. This process involves immersing the silicon carbide flat sheet membrane module in a chemical cleaning agent to fully dissolve and remove stubborn contaminants from the membrane surface and pores, thereby restoring membrane performance.

03 Commonly Used Cleaning Agents and Cleaning Water Quality Requirements for Silicon Carbide Ceramic Flat Sheet Membranes

① Commonly Used Cleaning Agents

The following table lists commonly used chemical cleaning agents:

| Agent Type | Commonly Used Agent |

| Oxidizing Agent | Sodium Hypochlorite (NaOCl) |

| Alkaline Agent | Sodium Hydroxide (NaOH) |

| Acidic Agent | Hydrochloric Acid (HCl)/Citrate |

Note: Specific agent dosages can be adjusted according to actual site conditions.

② Cleaning Water Quality Requirements

The cleaning water used to dissolve the cleaning chemicals can be UF permeate, pure water, or other relatively clean water sources. The following conditions must be met:

| Item | Parameter |

| Total Hardness | <80ppm (carbonate content) |

| Staining Index (SDI) | <3 |

| Total Organic Matter | <8ppm |

| Iron Ions | <0.5ppm |

| Silicon Ions | <5ppm |

Note: The specific operation and cleaning water quality can be adjusted according to the actual site conditions.