18072885002

I. Case sharing

→ Project Name:

5m³/hr Brine Oil and Impurity Removal Tubular Membrane Project

→ Inlet parameters:

pH value: 10-11 (strongly alkaline environment);

Temperature (average, maximum, minimum): 40°C/70°C/5°C;

Solid content: 1%;

Oil content: 1%;

Inlet COD: ≥10000ppm;

Main chemical composition: oil, sodium chloride, polysiloxane, sodium methanol, sodium ethanol.

→ Technical parameters:

Strong alkali resistance, flux maintained >800LMH, recovery rate >80%;

Salt discharge rate is increased by 50% + brine quality is greatly improved, and the cleaning cycle is extended by 3~4 times.

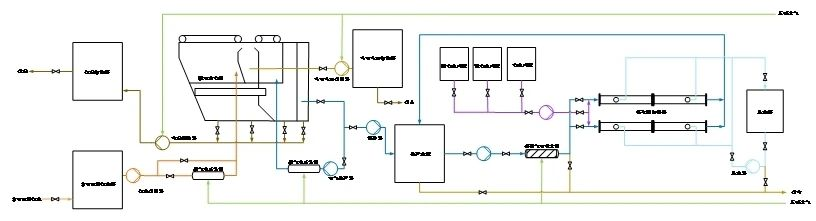

→ Programming:

According to the brine situation and process requirements, the oil removal clarifier + high flux membrane filter system is selected. Considering the working efficiency of the system and the convenience of the operation and maintenance of the system in the later stage, 4 high-flux membrane filters are used, 2 with 2 standby, and a chemical cleaning system is set up.

→ Process flow diagram:

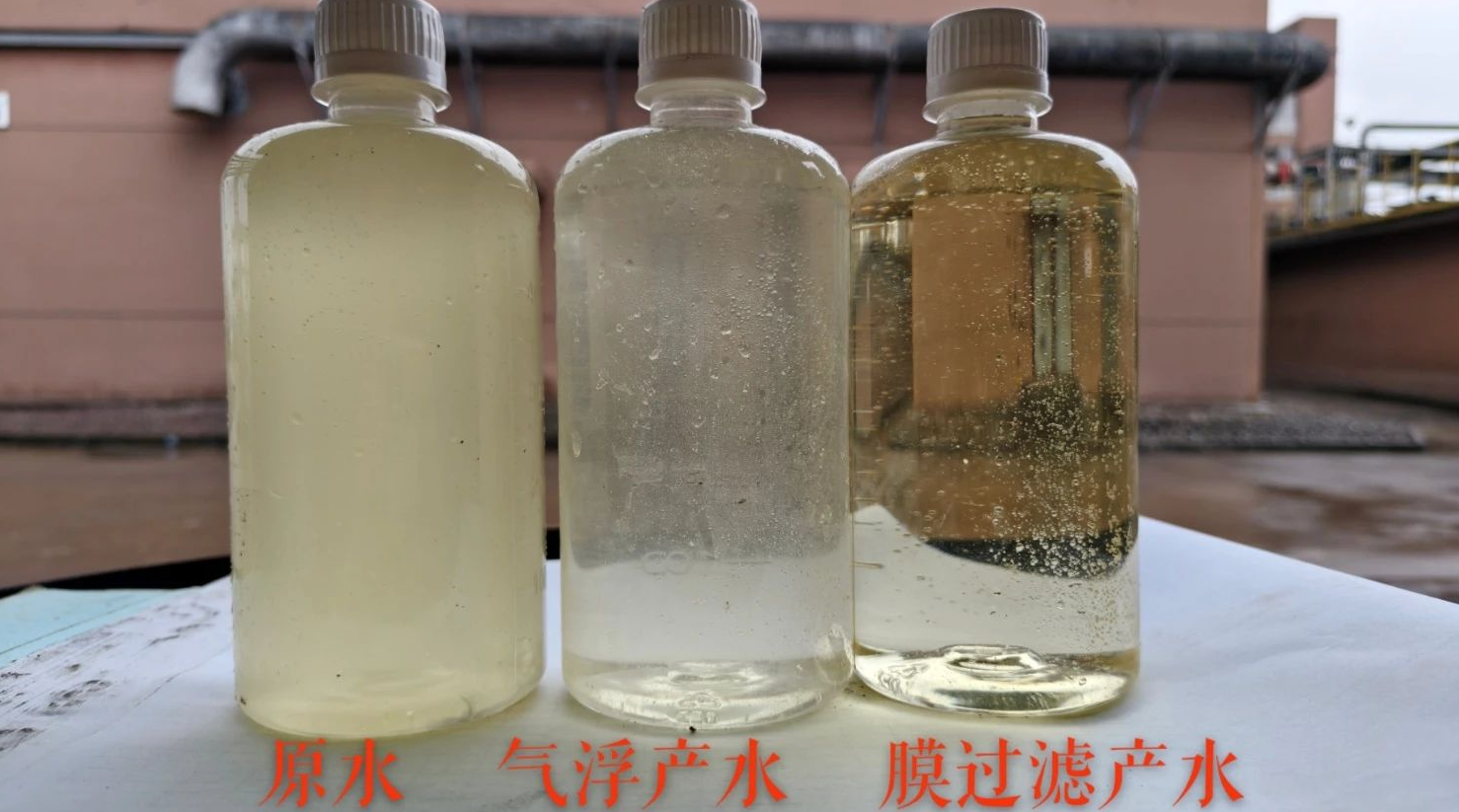

→Site photo:

II. silicon carbide ceramic membrane process analysis

The difficulty of oil-water separation in ultrafiltration membrane filtration process is that oil substances will form a thin film in the water, hindering the flow of water through the membrane holes, leading to membrane contamination and easy to plug the membrane. In addition, oil substances will combine with other substances in the water to form pollutants that are difficult to remove, further aggravating the clogging of the membrane. However, our silicon carbide ceramic membrane has high porosity and efficient filtration performance, excellent chemical stability and corrosion resistance, high strength and durability, and the surface has a negative charge, which can effectively prevent the formation of a contamination layer on the membrane surface, and can easily realize the separation of oil and water.

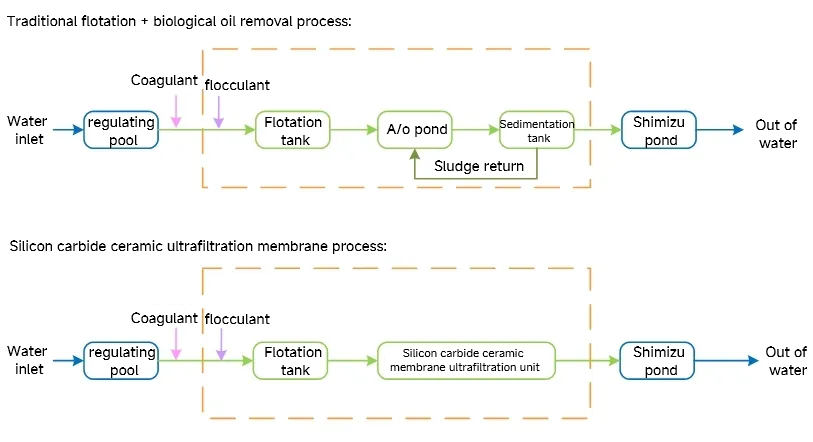

In the actual project, air flotation and silicon carbide ceramic membrane process is often used in combination: air flotation method will be high concentration of oily wastewater pretreatment, silicon carbide membrane and then the depth of purification, and ultimately realize the oil from the “visible floating oil” to the “molecular level of retention” of the whole process of control, the oil from the “visible floating oil” to “molecular level of retention”, the whole process of control. Compared with the traditional biochemical treatment covers an area of more economical, more concise process, but also can be stable <5mg / L of oil content in the effluent, while taking into account the processing efficiency and water quality accuracy, become the preferred option for oil-water separation projects.

III. the characteristics and advantages of silicon carbide ceramic membrane applied to oily wastewater

High-efficiency separation: high porosity and efficient filtration performance, efficient retention of floating oil, dispersed oil, emulsified oil and dissolved oil, high removal rate, low turbidity of the treated water, effectively reduce the COD and heavy metal content in the water, the water quality of the industrial reuse standards.

Anti-corrosion and anti-pollution: excellent chemical stability and corrosion resistance, high strength and durability, can be in the pH value of 0-14 acidic and alkaline environment, as well as high salinity, high hardness of water in stable operation, the surface of the self-contained negative charge, is not easy to be contaminated by oil, extend the cleaning cycle.

Long life: made of pure silicon carbide material with high mechanical strength and high temperature resistance, the service life is up to 15 years under normal working condition, which reduces the cost of frequent replacement of membrane modules.

Short process: the process is simple and compact, can be synergized with conventional pretreatment process, without complex equipment and cumbersome operation, easy to integrate, small footprint.

Low operating cost: low energy consumption, combined with the advantage of long service life, greatly reducing long-term operating costs and improving economic efficiency.

Flexible Adaptation: Membrane modules are modularized and can be flexibly combined according to the wastewater treatment volume, and can be adapted to centralized or distributed oily wastewater treatment systems.

Resource recovery: metals, organic matter and other valuable substances can be recovered from the retained concentrated water during the treatment process, realizing the reuse of resources and contributing to energy saving and emission reduction.