18072885002

This issue shares the technology of silicon carbide membrane applied to steel mills for flat water recycling.

I. Analysis of sources and water quality of leveled wastewater

The process of cold rolling production in steel mills includes pickling, cold rolling, annealing, degreasing, hot-dip galvanizing, leveling, grinding and other process sections. Cold rolling wastewater includes neutral salt and chromium-containing wastewater, acidic wastewater, concentrated oil wastewater, dilute alkaline oil wastewater, leveling liquid wastewater and so on.

Leveling wastewater mainly comes from the steel mill leveling and straightening process, which is mixed by leveling water, high-pressure rinsing water and leveling liquid wastewater. Although the emission of this kind of wastewater is relatively small, but the pollution load is extremely high, which contains a large number of suspended particles, oil pollutants, as well as iron (zinc) powder and other heavy metals, the treatment is difficult. In addition, part of the unit leveling water contains a small amount of leveling liquid, which is not recycled after the use of the leveling machine, which not only causes environmental pollution, but also leads to the waste of leveling liquid resources. Therefore, the core of the recycling of leveling wastewater lies in effectively retaining the effective components of the leveling liquid while removing pollutants such as oil.

II. case sharing - a cold rolling mill source emission reduction transformation flat water recycling device project (has been put into use)

1. Process analysis

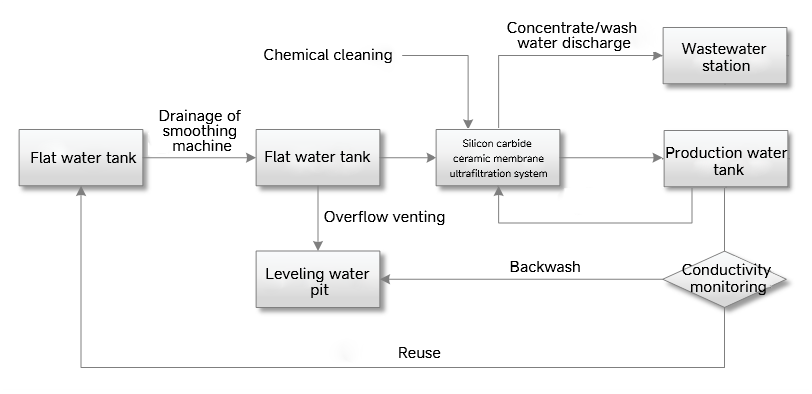

Figure 1 Leveling water recovery process

The leveling wastewater is first discharged into the raw water tank and then into the silicon carbide ceramic membrane ultrafiltration system for treatment. After ultrafiltration, clean produced water is discharged into the produced water tank, while organic matter, suspended solids and other pollutants are retained by the membrane and discharged out of the membrane system with the concentrated water. Produced water is monitored for conductivity and returned to the leveling tank for reuse after the water quality meets the standard; if it does not meet the standard, it is discharged into the leveling water pit. The original water tank is regularly overflowed and emptied to the leveling water pit. During the operation of the ceramic ultrafiltration membrane system, backwashing and chemical cleaning are required periodically to remove the pollutants adhering to the membrane surface. The cleaning wastewater is discharged together with the concentrated water into the wastewater station for secondary treatment.

2. Effectiveness analysis

Silicon carbide ceramic membrane ultrafiltration system can effectively and stably recover 80% of the leveling solution:

- Retaining the effective components of the leveling solution: the components of the leveling solution all have water-soluble substances (mainly ethanolamine), all of which can pass through the silicon carbide ceramic ultrafiltration membrane;

- Effective removal of heavy metals and oil pollutants: the interception rate of silicon carbide ceramic ultrafiltration membrane for metal powder (iron, zinc powder) is close to 100%, and the content of oil pollutants in the produced water can be reduced to <0.1mg/L;

- Reduced operating costs: through the test, the silicon carbide ceramic ultrafiltration membrane system can realize high-throughput continuous operation, and the interval time between single flushing can be more than 200h.

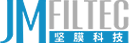

3. Pictures of the scene

III. Silicon Carbide Ceramic Film Analysis

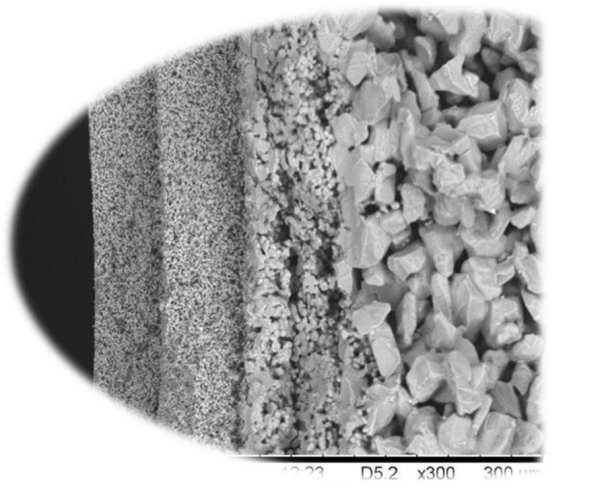

Silicon carbide ceramic ultrafiltration membrane is made of high-purity silicon carbide fine powder through recrystallization and sintering technology, which has the characteristics of high flux, corrosion-resistant, easy to clean, and long service life, and it is the membrane material with the best hydrophilicity and anti-pollution ability at present. Silicon carbide ceramic ultrafiltration membrane sintered at high temperature, sintering temperature up to 2400 ℃, in the sintering process between the sintered neck of the silicon carbide aggregate is solid → gas → solid phase transition process, no liquid phase transition, the pore opening rate of up to 45% or more (is the highest of the current inorganic materials), and filtration channel between the performance of a high degree of connectivity.

Fig. 2 Microstructure of pure silicon carbide membrane

Silicon carbide membrane is a new generation of inorganic membrane products with high flux, corrosion resistance, easy to clean and long life, which is made of pure silicon carbide particles through recrystallization process.

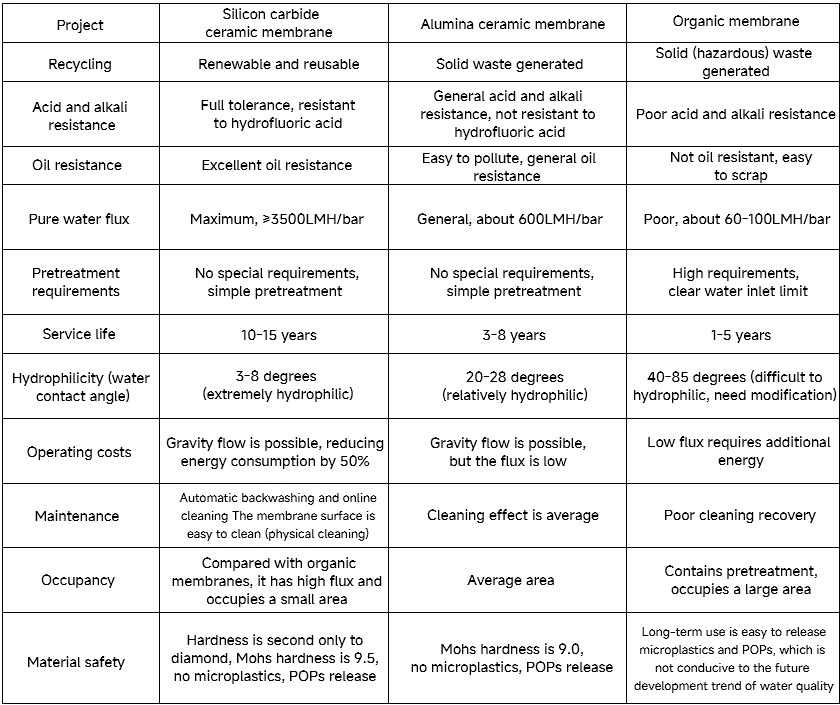

Performance Comparison of Silicon Carbide and Other Films